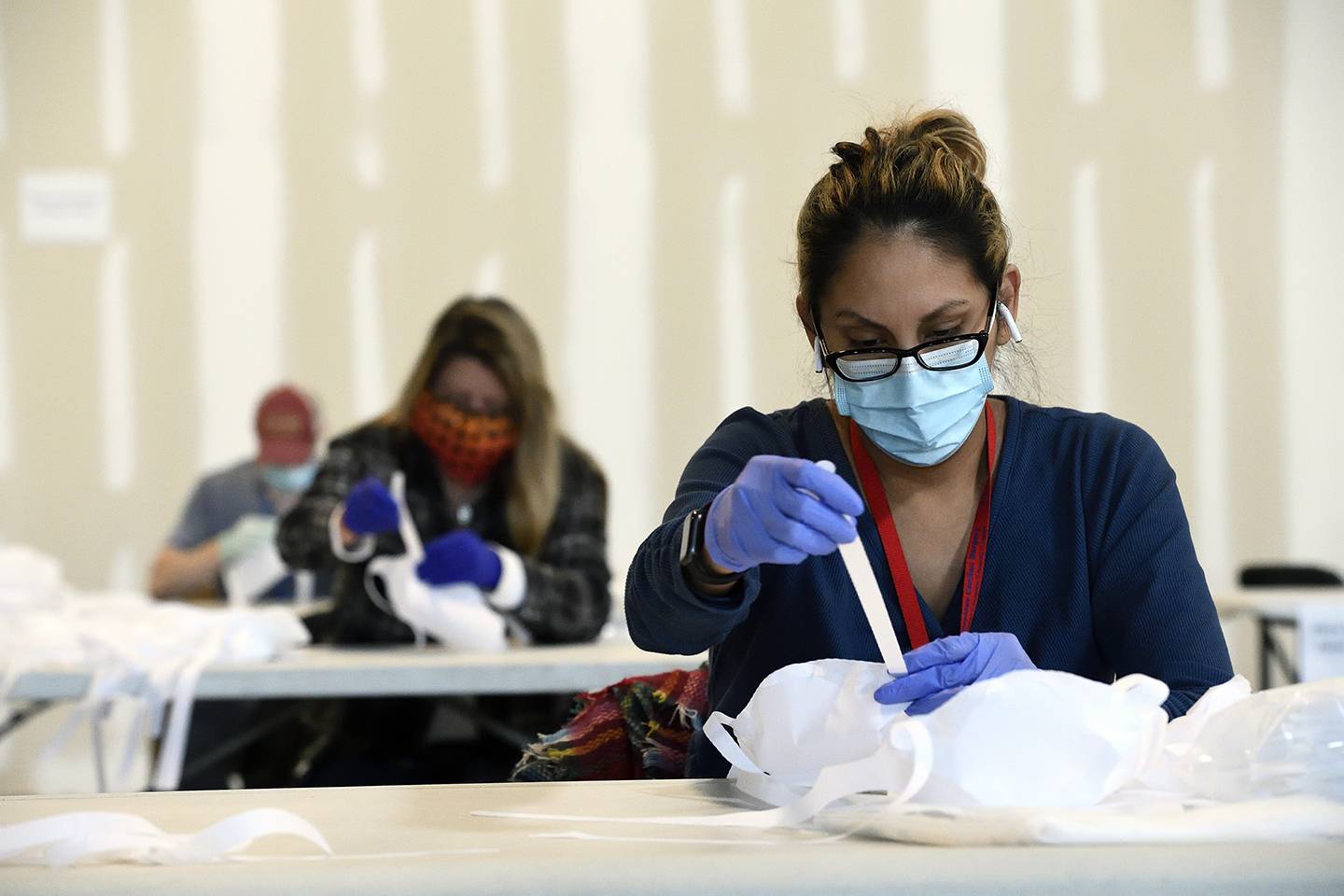

The Johns Hopkins Health System was able to deploy a fresh supply of no-sew face masks to its nonclinical staff and asymptomatic patients last week in the midst of the coronavirus pandemic, thanks to Under Armour and the efforts of Hopkins volunteers.

The 20,000 fabric masks—a form of personal protective equipment, or PPE—will help prevent the spread of the coronavirus in compliance with the health system's universal masking policy, according to Michelle Azotea, director of project management and implementation for the Johns Hopkins Health System Supply Chain.

The Baltimore-based sports performance product company delivered the masks to Johns Hopkins Hospital on Monday, April 6. They were manufactured at Under Armour's Lighthouse innovation facility and taken to the Johns Hopkins Health System Consolidated Service Center, where 50 employee volunteers were standing by to transform the flat-packed masks, with a few origami-style folds and tucks, into wearable protective gear.

"Masks appear to be a crucial strategy for reducing transmission of COVID-19," said Paul B. Rothman, dean of the medical faculty and CEO of Johns Hopkins Medicine. "As we move to ensure that everyone at Johns Hopkins Medicine has an adequate supply, we are so thankful for support from local businesses and community groups."

The masks are the second contribution to the coronavirus cause from Baltimore-based companies founded by Kevin Plank—local distillery Sagamore Spirit collaborated with Johns Hopkins pharmacists and supply chain team members in March to craft 54,000 liters of hand sanitizer for health system employees.

"Once again, Kevin Plank and Under Armour are doing all they can to help us," Rothman said. "Their spirit and effort are inspiring."

Like Sagamore Spirit, which converted 100% of its operations from rye whiskey mash bills to corn ethanol in less than 10 days to support the hand sanitizer effort, the Under Armour team is repurposing its Baltimore innovation hub, equipment, talent, design, and labor to help health care systems defend against coronavirus. Under Armour's high-speed fabric cutting machines are cutting nearly 100 pieces of fabric at once to scale to 300,000 no-sew masks per week. The company is partnering with area health care providers, including the University of Maryland Medical System and MedStar, to deliver these much-needed supplies until the gap can be filled within the traditional supply chain.

Image caption: Volunteers assemble no-sew face masks supplied by Under Armour for non-clinical staff and asymptomatic patients to wear in the midst of the coronavirus pandemic.

Image credit: Will Kirk / Johns Hopkins University

"When the call came in from our local medical providers for PPE, we just went straight to work," said Randy Harward, senior vice president of advanced material and manufacturing innovation at Under Armour.

Following recommended guidelines for social distancing, the Hopkins volunteers began assembling the masks Tuesday morning. Once constructed, the masks are individually bagged and placed in boxes of 20 for distribution throughout the health system. Thanks to the volunteers' efforts, the masks made it to the hands of nonclinicians and asymptomatic patients starting Wednesday, Azotea said.

"The amount of support we have received from the Hopkins community has been overwhelming," Azotea said. "To date, 1,000 volunteers have come to the Consolidated Service Center to support our response to this pandemic. The work of these volunteers has been key to ensuring we're protecting our staff on the front lines."

Tagged community, pandemic, coronavirus, ppe, covid-19, medical supplies