Baltimore Spirits Company is using its small-batch whiskey-making skills to produce hand sanitizer for the Baltimore community as it confronts a global coronavirus pandemic.

So far during the COVID-19 outbreak, the five-person team working out of Union Collective in Hampden has made at least 3,000 gallons of the sanitizer alongside its regular spirits, says founder and CEO Max Lents. The company is producing it to support small, frontline businesses and health care workers who don't have access to the dwindling worldwide supply, while also helping larger organizations like Johns Hopkins University and Medicine maintain their supplies of PPE, or personal protective equipment. So far, Hopkins has purchased 265 gallons from Baltimore Spirits.

"Small businesses are the lifeblood of our communities," says Alicia Wilson, vice president for economic development for Johns Hopkins University and Johns Hopkins Health System. "Johns Hopkins is grateful for the partnership with small local businesses, like Baltimore Spirits Company, whenever the opportunity presents itself. Baltimore's small businesses, during this time of uncertainty, demonstrate the grit and innovative spirit that makes us all proud to call Baltimore home."

Lents is quick to point out that Baltimore Spirits is one of many small businesses in Baltimore and beyond using their know-how to help out.

"We're doing this because we have an opportunity to help," Lents says. "There's a ton of people—whether they're quarantined in their house and they're making masks or they're a small distillery making hand sanitizer—who are trying to do their part for their local community, and that's one of the things that makes Baltimore a beautiful place. So it's really more of a community move for us than a business pivot, so to speak."

In the early days of the pandemic, Baltimore Spirits realized that a bad-tasting, high-proof alcohol waste product from its normal operations could be used to make bootleg hand sanitizer—it wouldn't meet World Health Organization specifications, but it could be easily made in small amounts, Lents says.

"After looking at some internet guidance on how to make hand sanitizer, we realized that this waste product had a high enough proof that if we add some glycerin, we could have essentially a functional hand sanitizer," Lents says. "A lot of distillers across the country started doing similar things, and different local governments realized that there was a big shortage and a bunch of qualified people who understood how to work with alcohol and how to blend it to a very precise proof."

Once the official call came from the state government to allow distilleries to make hand sanitizer to WHO specs, the team had to explore new supply chains to find required elements like hydrogen peroxide and bottling materials.

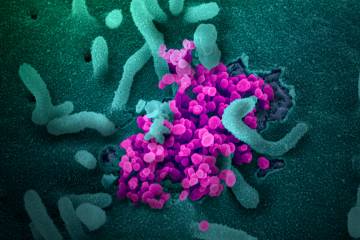

Image caption: Eli Breitburg-Smith, founder and head distiller of Baltimore Spirits Company, prepares a batch of hand sanitizer.

Image credit: Will Kirk / Johns Hopkins University

"We had already sourced a small amount of glycerin for our little in-house version, but we had to source it in bulk to really make a meaningful difference," Lents says. "We are a very by-the-bootstraps kind of company with a small, dedicated team. So there's not an automatic bottling system or robotic blending tanks that are doing all this stuff. We are weighing everything manually, blending it together, bottling it by hand essentially, as much as we can just to do what we can."

Though the company's profit margin isn't what compelled Baltimore Spirits to make hand sanitizer, Lents says that the steady flow of work to add hand sanitizer to their production runs means the small staff has remained on the payroll at a time when other small businesses are struggling to stay afloat.

"We're a long-hours company to begin with," Lents says. "Making spirits just requires long days. So we're already very well prepped for split shifts and keeping everybody tight. But so far, we haven't had to lose any of our full-time employees, which is really awesome, and everybody's getting their full hours, if not more. We're certainly grateful that it's working and it is an income stream and everybody's trying to piece together a living right now, but we're in it to help."

Tagged community, pandemic, coronavirus, ppe, covid-19, medical supplies