You can hear the whizzing, banging, clanking, and zooming of the Whiting School of Engineering Machine Shop from hundreds of feet away. It is here in the Wyman Park Building, in five separate workshops, that Rich Middlestadt oversees a revamped operation capable of producing everything from the simplest parts for an undergraduate design project to the most sophisticated elements necessary for advanced scientific research.

"We've been a little busy," says Middlestadt, the manufacturing manager charged with consolidating 11 workspaces across the Homewood campus, as he opens the door to the Student Machine Shop. Inside, senior biomedical engineering major Sean Bailey, a student machinist wearing protective eye gear and a dark jumpsuit, is teaching undergraduate mechanical engineering students about the thickness of metals. As the lathe whirls, curls of metal drop to the floor like shiny pencil shavings.

The Whiting School of Engineering spent roughly $1 million to upgrade the machine shops over the summer, adding more than $500,00 in equipment that includes a $120,000 Rapid Prototype Machine (aka 3-D printer) with support equipment and a $100,000 Wire EDM Machine that, as Middlestadt puts it, "uses electricity to cut metal like butter." Now students can be trained on the most advanced equipment and learn the economics of using materials, time, and tools efficiently to achieve design purposes. Postdocs and researchers can order parts from the Professional Machine Shop across the hall, or from the Advanced Manufacturing Laboratory upstairs. These jobs are provided on a fee-per-service scale.

Upstairs in the Advanced Manufacturing Lab, Niel Leon, the design consultant, is working on an even more sophisticated machine to turn around a job for postdocs working in Professor Noah Cowan's Locomotion in Mechanical and Biological System laboratory.

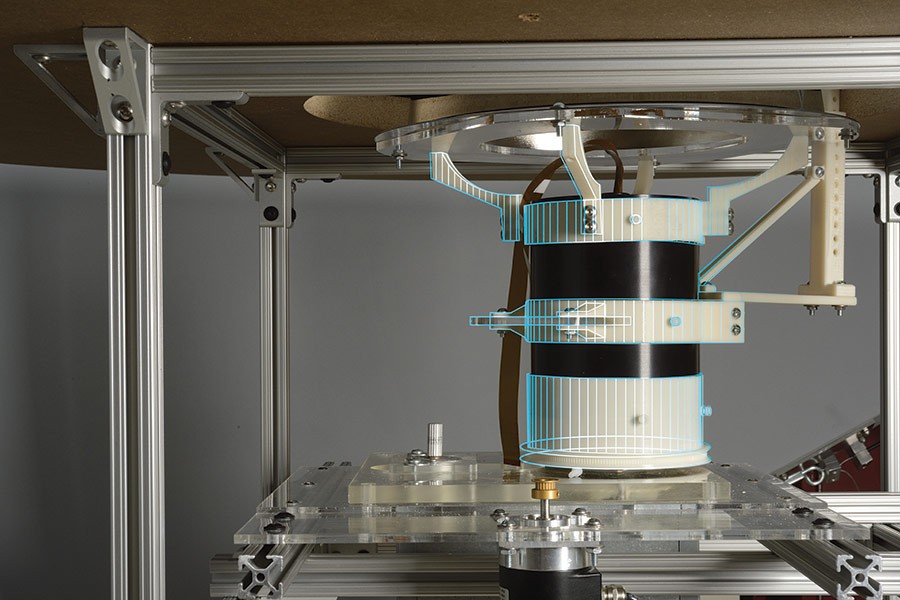

The 3-D printer turns the task of producing a part called a boom mount from a two-week ordeal into an overnight job. What's more, the printer produces a single piece, eliminating the need to weld or drill holes. The cost reduction: about 50 percent. "This is like driving a Ferrari," says Leon. "No, actually, this is like having a flying car."

Three-D printing allows designers to produce solid objects of virtually any shape from a digital model. Instead of welding pieces together, the machine creates a single part by layering liquid material that hardens as if baking a layered cake. Each layer can be as thin as 0.005 of an inch thick.

Students have access to this "high-tech toy," Leon says, if trained properly. Last year, he worked with biomedical engineering senior Neil O'Donnell on his Johns Hopkins Business Plan company called KidVentions, which utilizes 3-D printing so kids can custom design toys. The idea won first place. So what did Leon produce for KidVentions? "I built a 3-D model of a little flying pig," Leon says, with a smile.

Posted in Science+Technology

Tagged mechanical engineering, engineering