- Name

- Lisa Ercolano

- lde@jhu.edu

In laboratories and design spaces across Johns Hopkins University's Whiting School of Engineering, students are racing against the clock to put finishing touches on design projects as varied as a self-sterilizing water bottle, a system that uses drones to autonomously track and manage warehouse inventory, and a computer vision-based system that tracks workflow in an operating room.

These projects—more than 150 in all—will be presented to industry sponsors and mentors, faculty members, clinicians, alumni, and fellow students at Tuesday's Design Day, an annual event that showcases students' abilities to translate theoretical knowledge into practical and creative solutions to real-world problems.

The concept of a "design day" began 35 years ago in the Department of Mechanical Engineering but has now grown to include all nine Hopkins Engineering departments, as well as the Center for Leadership Education.

"Design Day is a celebration of our undergraduate and graduate students' innovation, creativity, and energy," said Ed Schlesinger, dean of the Whiting School.

For one of the projects, faculty from the Johns Hopkins Department of Anesthesiology and Critical Care Medicine asked mechanical engineering students to devise a solution to a serious problem they see too often in the emergency room: riding lawnmower-related injuries to children. Common reasons these life-changing injuries occur is because a running child slips under a mower, a parent reverses the mower and doesn't see a child, or a child falls off the mower when riding on a parent's lap.

"While we knew the main causes of these injuries, our biggest challenge was that we don't know exactly how these injuries happen in real time," said Garrett Ung, a senior mechanical engineering major. "Recordings of these accidents as they happen obviously aren't available, so we had to go based on our research and consider different scenarios."

Working with Ung on the project are seniors Natalie Myers, Rafael de la Tijera Obert, Tommy Liang, and junior Aloysius Teng.

"In the beginning, we probably threw 30 ideas at the problem, just to find one that even had a shot at preventing lawnmower injuries. We just had to keep working through ideas, as practical or wild as they were," Myers said.

The team developed two safety mechanisms that address the most commons causes of lawnmower injuries: a computer-vision sensor on the rear of the lawnmower that can detect a child and send a signal to stop the lawnmower, and a safety guard that prevents children from getting too close to the blades should they fall off a parent's lap.

During the design process, the team was committed to keeping the end-user of their product in mind.

"Our designs are not lawnmower-specific," de la Tijera Obert said. "We can take these new safety mechanisms and, with very few modifications, put them on any type of lawnmower."

Most projects to be presented at Design Day involve partnerships with external sponsors or other Hopkins divisions. As is the case with the lawnmower team, teams across the Whiting School were handed real-world problems and tasked with delivering real-world solutions. They spent months brainstorming approaches, refining ideas, and finalizing their prototypes with the help of faculty advisors and industry experts.

In the Department of Electrical and Computer Engineering, senior Sarah Denenberg and junior James Roberts will present a 3D-printed prototype of their project: a secure medication dispenser that alerts a user when it's time to take their medicine, but also lets them know if they've already taken their prescribed dose.

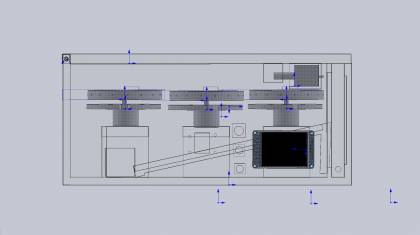

Image caption: 3D model of a device to prevent patients from taking more than one dose of medicine per day

"With our device, you only get as much medication as you're supposed to get, when you are supposed to get it," Denenberg said. "Another feature is that this dispenser has fingerprint security that keeps medication in the right hands."

According to Roberts, creation of the mechanism to dispense the correct dosage really challenged team members to apply knowledge gained in computer engineering courses.

"We understand how a user might interact with sensors," he said. "We know how to program, and we know how to make digital components behave correctly. All those skills came into play as we developed our product."

That, in a nutshell, is the objective of Design Day, according to Nathan Scott, associate teaching professor and head of the Department of Mechanical Engineering's Senior Design Program.

"The first years of the engineering degree are rich in engineering-science content, and the problem sets are abstract," he said. "But at some point in the junior year, the emphasis starts to shift toward solution of real-world, open-ended, messy problems, in the company of older engineers from industry and faculty. I am very proud of the achievements of all our seniors, their willingness to work outside their comfort zone, and their courage to tackle problems that are dark with the unknown."

A complete schedule of this year's Design Day events is at the event website.

Posted in Science+Technology, Student Life

Tagged engineering, design days