It sounds like science fiction, but Johns Hopkins scientists are making food from air.

The revolutionary project could someday help feed soldiers in rugged, hard-to-reach places or sustain victims of natural disasters until normal supply chain operations can resume.

"Getting food where it's needed can be a really big challenge," says project lead Collin Timm, a chemical and biological engineer at the Johns Hopkins University Applied Physics Laboratory. "But what if we had a technology that allowed us to produce food locally, rapidly, and on demand so that we can alleviate some of the logistical burdens of getting food to people?"

The Challenge

Modern food production processes require a lot of time, resources, and energy, Timm says. To make a loaf of bread, for instance, farmers first have to plant and tend to wheat. Months later, they harvest and sell their crop. The wheat then needs to be milled into flour, processed, and eventually combined with other ingredients and baked. Finally, it must be packaged and delivered to stores. Nearly every stop along this supply chain requires transportation and logistics.

But what if this approach is not possible because flooding prevents truckers from reaching grocery stores or a mission requires troops to spend weeks in the desert? How do we feed people then?

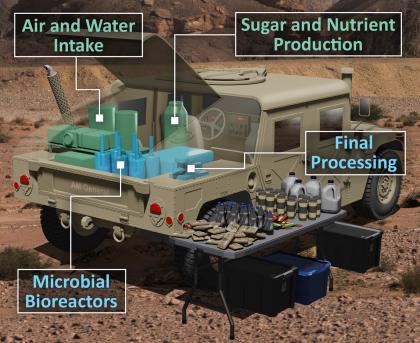

That's the challenge put forth by the Defense Advanced Research Projects Agency, the research and development arm of the U.S. Department of Defense. DARPA selected four research projects—including a team comprising scientists from APL and other Johns Hopkins University divisions, as well as North Carolina State University and Meridian Biotech—to figure out how to produce nutritious, appetizing food using water, air, and electricity, with minimal to no supplementation. At the end of the four-year, $15.4 million project, the APL-led team aims to have a compact system that can fit in the back of a military vehicle and churn out a vanilla pudding–like product with a texture similar to Greek yogurt. That food will not only be tasty, the researchers promise, but also packed with all the macronutrients, vitamins, and minerals humans need to survive.

Image credit: Johns Hopkins APL

How It Works

APL's in-development system uses electricity, water, and engineered microbes to pull carbon dioxide, nitrogen, and trace minerals—such as magnesium, calcium, and iron—out of the air. Next, an electrochemical process involving common metals like tin and copper converts the CO? into acetate. From here, researchers can trigger a chemical reaction or introduce microbes to convert the acetate into simple sugars like glucose.

Together, the simple sugars, nitrogen molecules, and minerals form feedstock. When specially engineered microbes eat this feedstock, they can produce macronutrients—protein, carbohydrates, fat, and fiber, which are the building blocks of food—as well as vitamins. This part of the process is something many eaters are likely already familiar with: fermentation, which also gives us many foods we enjoy today, such as kimchi and yogurt, Timm says.

The team is also developing microbes that can produce texturing agents and flavor molecules.

"As humans, we don't just eat food for nutrients—we also enjoy the process," Timm says. "We don't want to feed people microbe sludge; we want to have it be a delicious, palatable food. It has to be, or they won't eat it."

Scaling Up

Timm and his team are still developing these steps, which will eventually form an integrated food-on-demand system.

They're also working to scale up their equipment and processes. DARPA has outlined two scenarios for the technology's use: In one, the system must fit on a Humvee and be able to feed a small military combat unit deployed to a rugged environment for 45 days. In the other, it must fit inside a 20-foot shipping container and feed 100 civilians for 21 days after a natural disaster or other humanitarian crisis.

"It's a complex project, but we have the team and the vision to be able to get there," Timm says.

Posted in Science+Technology